Loading... Please wait...

Loading... Please wait...Contract Manufacturing

Under the umbrella of ISO13485, Baldwin Medical can manufacture your own branded device.

The combination of our skilled staff, state of the art equipment and over 250 sq metres of Class C Cleanroom is at your disposal to make your single use product concept come to life.

Our design and development process will optimize your outcome. It selects raw materials, components and packaging materials. It also naturally includes risk analysis and sterilization validation. We work with our customers to ensure that the products are of the highest possible quality.

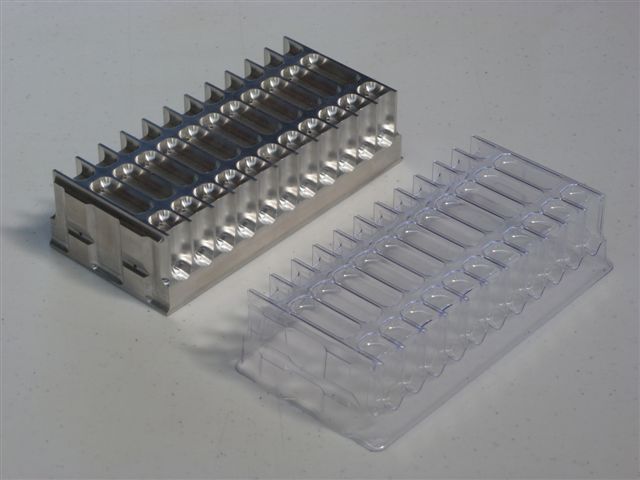

We routinely manufacture batch sizes from 100 units to 100,000 units. We also design injection moulding tools and develop machinery for assembly if required.

Our current cleanroom processes offered are RF welding, printing, blister packing, thermoforming, assembly – both manual and automatic. We routinely utilize robotics in our assembly to provide cost effective, highly consistent results.

We use your artwork and logo to fully brand your product and packaging. Current customers also utilize our sales release procedure, warehouse and logistics to ship products directly to their clients.

For further information please contact us